Acoustic

Acoustic solutions adapted for sound comfort.

Documentation

Acoustic comfort

Acoustic comfort corresponds to the feeling of well-being in a pleasant sound environment, where noise is controlled.

It is not limited to a decibel evaluation but also includes the quality of sounds and their influence on our concentration, communication, rest, and health.

Fabrics, like all materials, have acoustic properties that vary according to their structure and how they are used in correlation with their environments This is why it is important to consider 3 parameters:

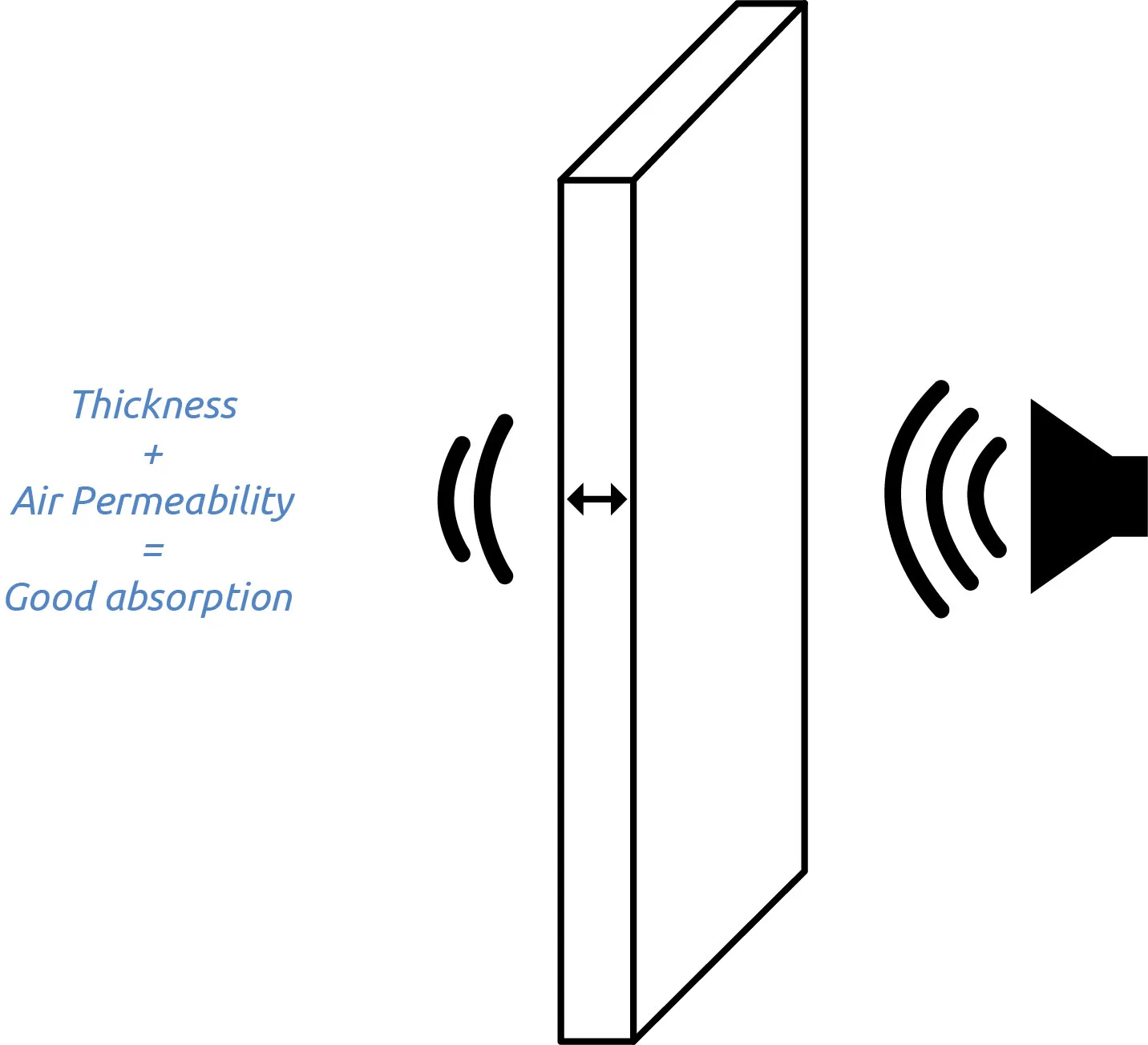

1. Viscous Absorption

This is the dissipation of sound through a material (mainly high-pitched sounds). Generally speaking, the thicker and more air-permeable the material, the better its absorption potential.

A fabric that is too tightly woven can cause much of the sound to be reflected back, resulting in a lack of absorption. It also increases reverberation time, which will reduce acoustic comfort.

2. Mechanical absorption

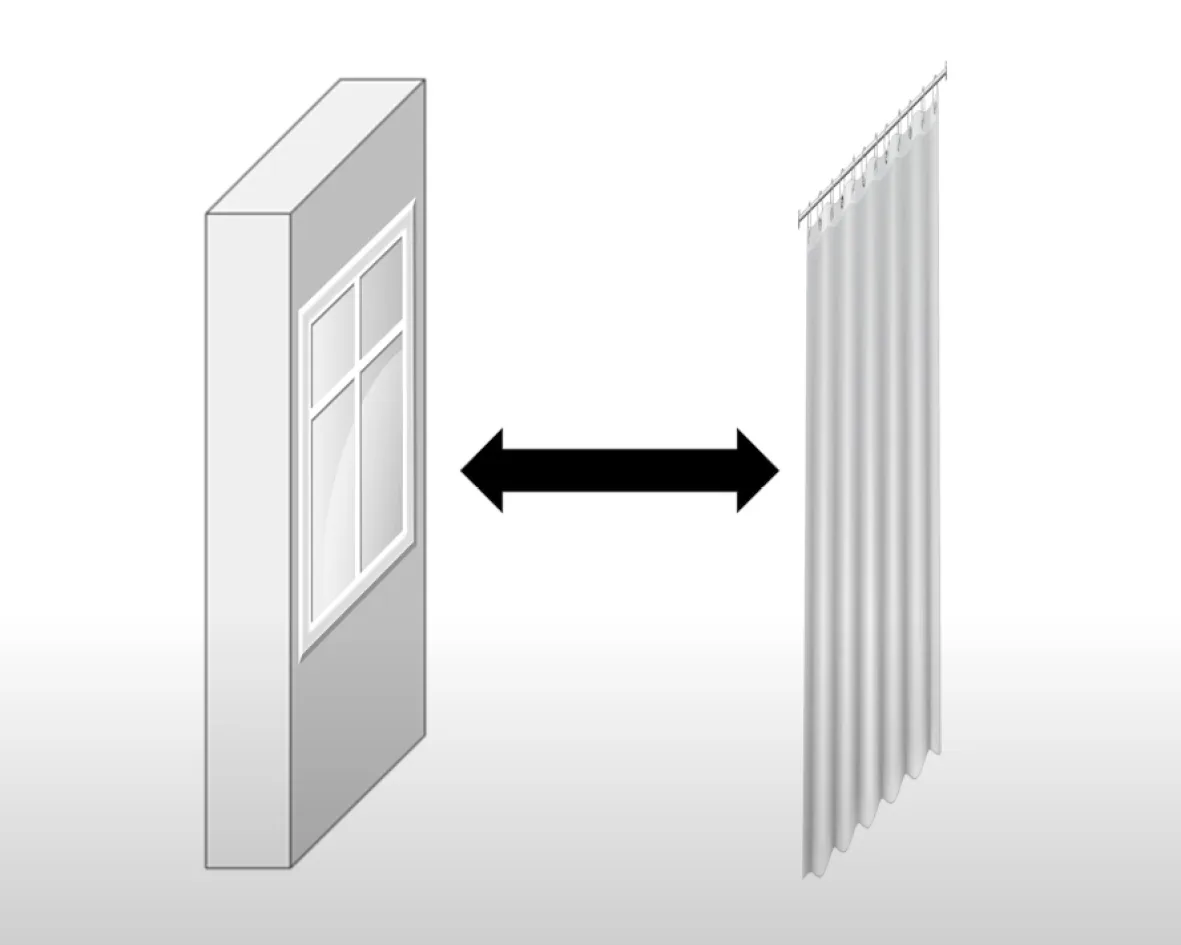

This is the “air gap*” effect. This layer of air acts like a car’s suspension system and absorbs sound (mainly low frequency). However, it needs to be adjusted correctly: neither too far nor too near.

For curtains, the optimum distance depends mainly on their composition and installation.

Example of the impact of the air gap on the acoustic performance of our BOREAL fabric: with 40% fullness installed 12 cm from the window, we obtain an acoustic coefficient of 0.90, whereas the same curtain with the same fullness has a coefficient of 0.65 if it is installed 3 cm from the window. This represents a difference in performance of almost 38%.

*An air gap is an empty space created between two materials – in our case, between the curtain and the window.

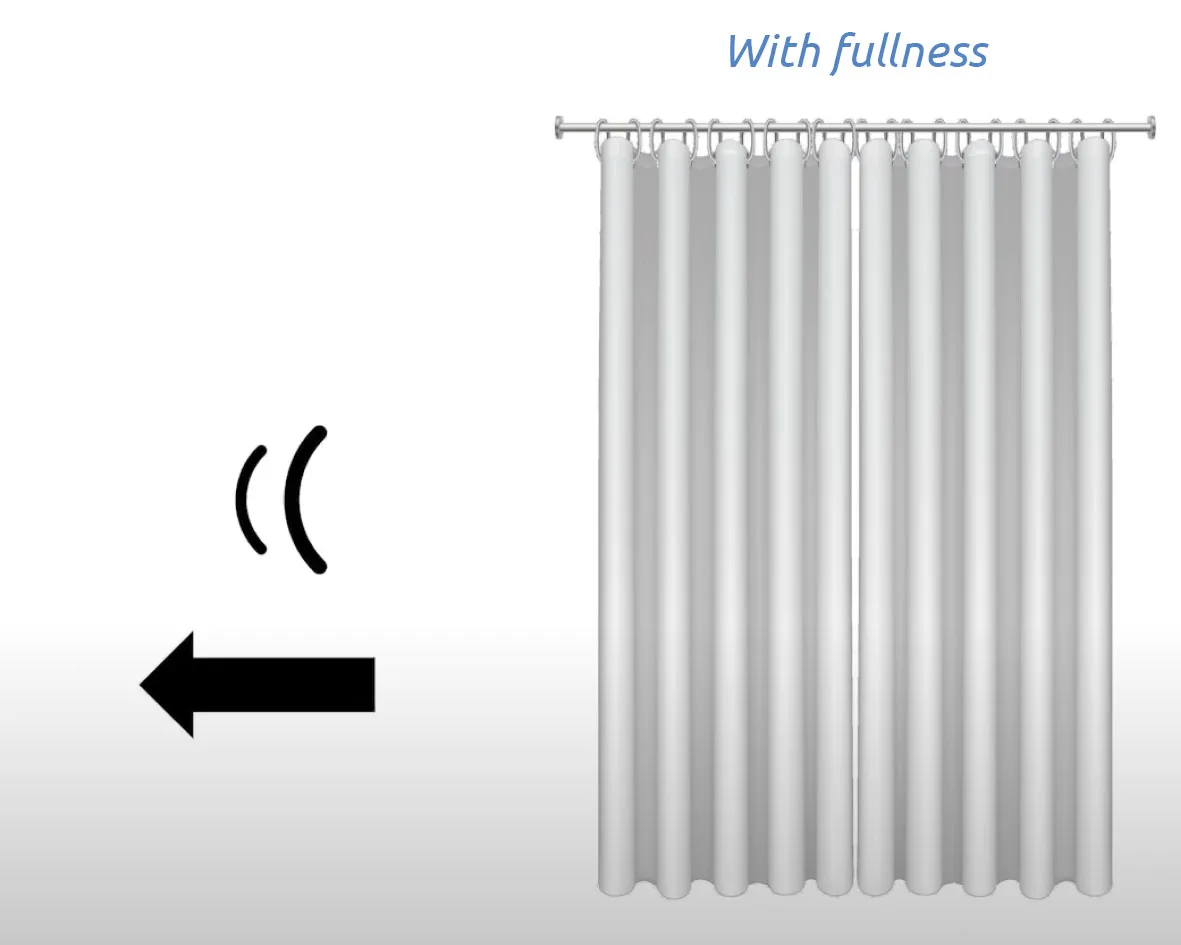

3. The influence of the fullness of the curtain

The fullness* increases the exchange surface between the curtain and the air in which the sound energy is propagated, thus increasing the possibility of the energy dissipating both viscously and mechanically. The natural movement of the curtain, which is related to its size, also improves sound dissipation.

*The fullness of a curtain refers to the quantity of fabric used to make it in relation to the width of the window or curtain rod. More fullness will give a more draped effect and more pronounced pleats, while less fullness will make the curtain flatter with shallower pleats.

By intelligently adjusting these 3 parameters, a curtain’s acoustic performance can be significantly improved.

Reverberation time: Reverberation time is also an important factor when considering acoustic comfort. This is the persistence, or extinction time, of a sound after the sound source has stopped, the result of multiple reflections off surrounding walls and surfaces. This phenomenon varies according to the sound frequency and the configuration of the

space.

IMPORTANT: as you can see, the performance of a curtain depends not only on the fabric itself, but also on how it is positioned (in relation to the window and its fullness) and where it is installed.

Definition of the absorption coefficient

- Coefficient αw (sound absorption coefficient) :

The coefficient αw is obtained by calculating the difference between the incident sound energy (sent to the surface) and the reflected energy. This gives us the energy that is absorbed.

The αw coefficient varies from 0 to 1. For example, when incident sound emitted inside a room encounters a hard, smooth, heavy, reflective wall, the alpha will be 0. When it encounters an open window, which by definition reflects no energy and absorbs all of it, alpha will be 1.

As alpha varies according to sound frequency, this measurement will be taken over several frequencies. Frequency, measured in Hertz (Hz), is one of the properties of sound, alongside intensity and duration. It represents the number of vibrations per second. A low-frequency sound is perceived as low-pitched, while a high-frequency sound is perceived as high-pitched.

The αw coefficient is calculated in accordance with the ISO 11654 standard, and corresponds to the weighted average of the alpha coefficients measured by frequency across the whole one-third octave band.

*In acoustics, octave and one-third octave bands are segments of the frequency scale that facilitate the simplified analysis of a sound, such as a noise.

- NRC coefficient (noise reduction coefficient) :

The NRC coefficient is measured according to the ASTM C423 standard, which corresponds to the weighted average of the absorption coefficients of the material over 4 frequencies (250, 500, 1000 and 2000 Hz).

These 2 coefficients can be measured in 2 different ways:

– With an impedance tube, also known as a Kundt tube: this is a device used in acoustics to measure the sound absorption properties of materials. It works by generating acoustic waves in a cylindrical tube, which are then directed towards the sample of material to be tested.

This test enables us to carry out an initial analysis to determine the acoustic benefits of the fabric.

– In a reverberant chamber: this is a chamber where the surfaces reflect the sound waves in all directions (random incidence, known as a diffuse field), thus creating uniform acoustic pressure. This environment enables the fabric to be tested in a curtain configuration, with a defined fullness and air gap.

Product absorption class

Products can be categorised into different sound absorption classes determined by the value of the αw coefficient (the NRC is not involved in determining the class).

There are five absorption classes for products, ranging from A to E:

| Classes | Absorption coefficient |

| A | 0.90 / 0.95 / 1 |

| B | 0.80 / 0.85 |

| C | 0.60 / 0.65 / 0.70/ 0.75 |

| D | 0.30 / 0.35 / 0.40/ 0.45 / 0.50 / 0.55 |

| E | 0.15 / 0.20 / 0.25 |

| Non-classified | 0.00 / 0.05 / 0.10 |

You can find all these values in our acoustic performance data sheets, prepared for each product and available on request:

Tests conducted by

Your acoustic project

An acoustic solution is determined on the basis of precise specifications, for which SOTEXPRO can offer you personalised support through our partner network.

For example, a classroom will not be treated acoustically in the same way as a theatre, a cinema or a brasserie. and a curtain will not be treated in the same way as an acoustic panel.

It is therefore important not to select your fabric solely on the basis of the Alpha W or NRC coefficient.

As these are an average of the results obtained over a wide range of frequencies, from the highest-pitched sounds to the lowest. This is done in a standard configuration, which in most cases is different in reality.

Do you have a project?

Our sales team supports you and provides expert guidance on standards tailored to specific types of establishments (schools, hospitality, retirement homes, healthcare facilities, etc.).